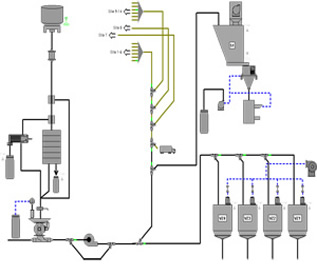

Dosing plant

- Overall equipment efficiency

- Creation of production plans

- Verification of manufacturing

- Master data and time registration

- Batch card

- Batch report

- Material management

- E mail or phone notification

- Cleaning and service management

- Free configuration of automatic journals and malfunction categorization

- Data exchange with business-management systems (SAP, Excel, etc.)

The overall equipment efficiency is a very mighty tool. It is possible to monitor the efficiency of every single part of your plant with the OEE. The specialty of this system is to identify and analyze the losses of the plant and these losses can be reduced with a verified action plan.

In addition, a lot of other handy functions can be integrated. For example, it is possible to log the material usage. Now, a minimum amount for every raw material can be set in the system. In case, this minimum amount isn’t in stock anymore, the system sends automatically an order to the supplier.

A weight note can be created automatically by means of a calibrated scale combined with our control systems. The big advantage of this system is that the weighing notes can also be used for creating a bill. This bill can also be sent directly to the business-management system (SAP etc.) of your company. Therefore no administrative costs occur, because everything was done by our control system.We are always keen to have a close contact to our customers and like to oblige their wishes.

Following, you will find a small listing of plants we have already realized with our control concept:

- Charge mixing plant at Dorfner Mühle

- Batch plant at Heinz Glas

- Batch plant at Zwiesel Kristallglas

- Batch plant at Schott

- Batch plant at OSRAM

- Batch plant at Swarovski

- Batch plant at Rodenstock